Industrial Automation

Manufacturers Face Growing Challenges

Businesses are facing challenges due to shortening product lifecycles, higher product variability, and supply chain disruptions. These factors are pushing companies to bring manufacturing closer to home. Additionally, the shortage of labor is affecting productivity, leading to errors, decreased quality and high turnover. Many companies are turning to collaborative robot to automate mundane tasks while freeing employees for more meaningful, higher-value work.

collaborative robot automate routine tasks, increase capacity, and are suitable for limited spaces.

Flexibile and Agile Operations

collaborative robot execute tasks with precision and repeatability, and are easy to program with minimal training, allowing manufacturers to quickly adapt to change.

Free Employees for Higher-Value Work

collaborative robot allow employees to focus on more important tasks, leading to higher engagement and reduced turnover. With collaborative robot, employees can achieve more.

Fast, Easy Deployment

collaborative robot are fast and easy to deploy, delivering ROI in weeks, not months or years. They have a long lifespan, providing even greater ROI. Ideal for Small and Medium-sized Enterprises and organizations looking to reshore or nearshore.

Get Started

Discover the PreciseFlex Difference

PreciseFlex robot offer superior performance, safety, reliability, energy efficiency, and compact design.

Highest Throughput

PreciseFlex Cobots

- The primary axis moves horizontally without the need for high-ratio reducers to support gravity loaded axes

- Extremely low gear ratios of 1:1 or 5:1, which allow teaching with near zero fricton

- Extremely low reflected inertia results in low collision forces

- Can move faster and accelerate at higher rates without compromising safety

Traditional Cobots

- Move axes vertically - against gravity - using harmonic drives a wear item and failure point) to lift the arm

- Move high gear ratios of 150:1 or more with high friction results in difficult hand-guiding for teaching

- Higher reflected inertia (2,000x more than PreciseFlex cobots) results in higher collision forces

- Must move slower and accelerate at lower rates to be collaborative

Most Reliable

PreciseFlex Cobots

- Mean Time Between Failure (MTBF) of 125k hours*

- Design life of 40,000 hours for PreciseFlex 400 and 3400

- Design life of 100,000 hours for PreciseFlex DD 4-axis, which uses direct drive motors. (the highest among standard cobots)

*Based on over 4.000 robots deployed for over 12 years. MTBF as stated here applies to robot only, and does not include the complete automation system. Robot reliability depends on the application and environment.

Traditional Cobots

- MTBF not published

- Design life not published. Harmonic drives typically last 20.000 hours

- Substandard reliability results in ongoing retrofits and recall notices

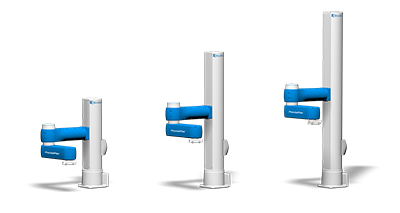

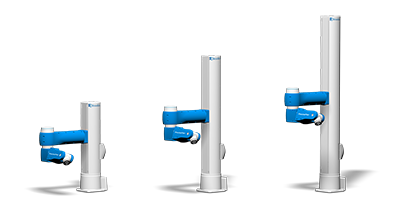

Highest Workspace Density

PreciseFlex Cobots

- Vertical column envelope maximizes workspace

- Ideal for moving vertically and reaching into shelves, machines, and instruments

- Extend robot reach with Collaborative Linear Rail (easy to program with coordinated motion)

- Ideal for mobile applications

Traditional Cobots

- Spherical envelope limits vertical reach

- Bulky wrist restricts access in narrow spaced

- External controllers and cables require extra floor space

- Larger footprint requires more floor space

- Third-party linear rails are expensive, clunky, and time-consuming to design and install

- Unsuited for mobile applications due to high power consumption, bulky external controller, and offset spherical work envelope

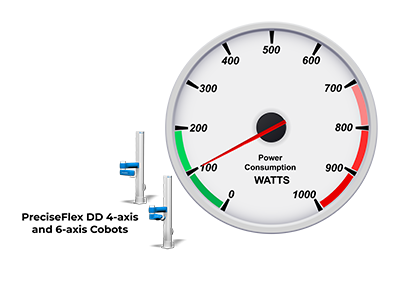

Most Energy Efficient

PreciseFlex Cobots

- 70 ~ 150W for moving payload at speed, using 1/3 the power of traditional cobots

- Up to 12 PreciseFlex 400 and 3400 cobots run on a single 120VAC/20A circuit

- Up to 15% additional power savings with DO Power Option

- Ideal for mobile applications

Traditional Cobots

- Consume more power due to vertical axis design and high-friction harmonic drives

- Wasted power dissipated as heat creates more inefficiency, requiring air conditioning in climate-controlled facilities

- Require up to 3X more power to do the same work

- Inefficient in mobile applications

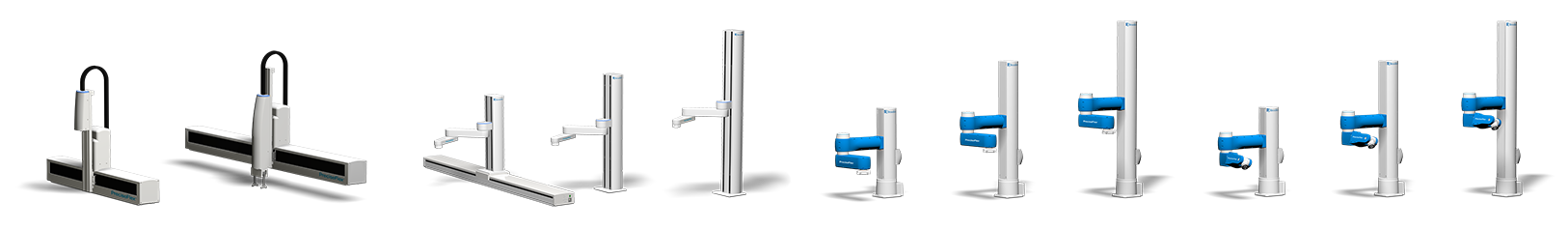

PreciseFlex Family of Collaborative Robots

(3kg payload) - Ideal for small parts handling, kitting, and electronics testing.

(10kg payload) - The latest generation of PreciseFlex robot with tall Z-axis and large cylindrical work envelop.

(8kg payload) - The latest generation of PreciseFlex robot with 6-axis articulation, tall Z-axis, and large cylindrical work envelop.

(3-6 kg payload) - The only collaborative Cartesian robot that offers a space-saving design with speed and safety.

Authorized System Integration and Distribution Partners

Learn about OUR partner Program