Life Sciences

At Brooks, we understand that automation has the potential to transform the life sciences landscape. By leveraging our expertise and advanced technologies, we provide our customers with the means to achieve efficient, accurate, and reliable testing, ultimately leading to improved outcomes for patients and researchers alike. Experience the future of life sciences with our pioneering automation solutions.

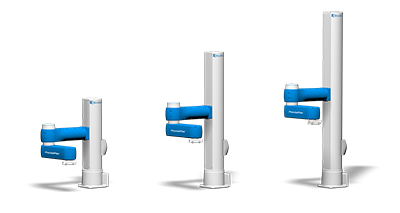

PreciseFlex Robots

PreciseFlex c3

(3 kg payload) - Based on the proven PreciseFlex 400 robot, the PreciseFlex c3 is optimized to meet the evolving demands of drug discovery and development labs. The PreciseFlex c3X has the same functionality as the PreciseFlex c3, but with an extended horizontal reach.

Learn More

PreciseFlex c5

(5 kg payload) - Designed to work seamlessly alongside people and delicate equipment, the PreciseFlex c5 Robot delivers precision and sophistication in any environment. Whether you're operating a manufacturing plant, streamlining a warehouse, or managing a laboratory, this PreciseFlex robot offers an unparalleled advantage

Learn More

PreciseFlex c10

(10kg payload) - The latest generation of PreciseFlex robots with a tall Z-axis and large cylindrical work envelope of 900mm.

Learn More

PreciseFlex 400

Sample Handler is ideal for benchtop applications where safety, ease of use, and space savings are critical.

Learn More

PreciseFlex 3400

(3kg payload) - Ideal for sample handling when more payload is needed.

Learn More

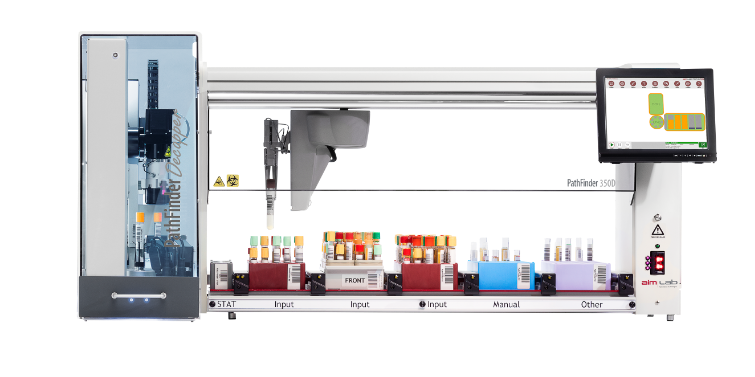

PathFinder Benchtop Systems

PathFinder Benchtop System

PathFinder™ benchtop systems are designed to automate the receipt, handling, distribution and storage of incoming samples in the Pathology Laboratory.

Learn More

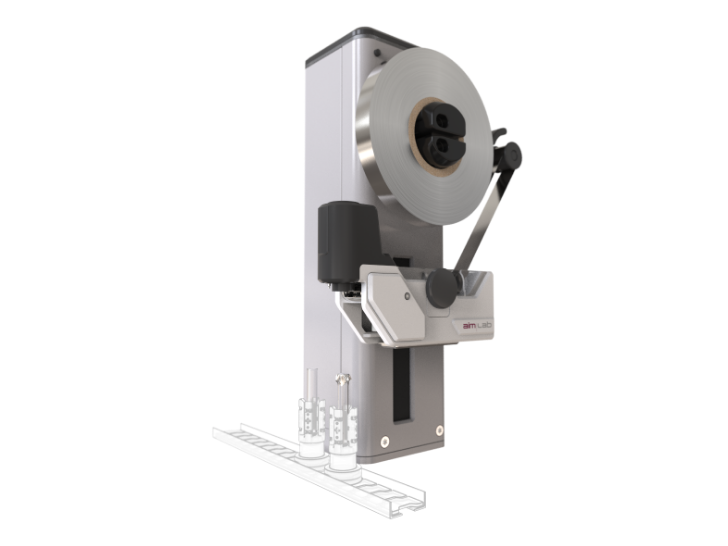

PathFinder OEM Modules

Tube Decapper Module

Designed to automate the pre-analytical function of decapping a specimen collection tube.

Learn More

Tube Sealer Module

Designed to automate the post-analytical function of sealing an open specimen collection tube.

Learn More

PathFinder + PreciseFlex

Extend the automation capabilities of your liquid handling systems to include decapping, sorting, and sealing.

contact us