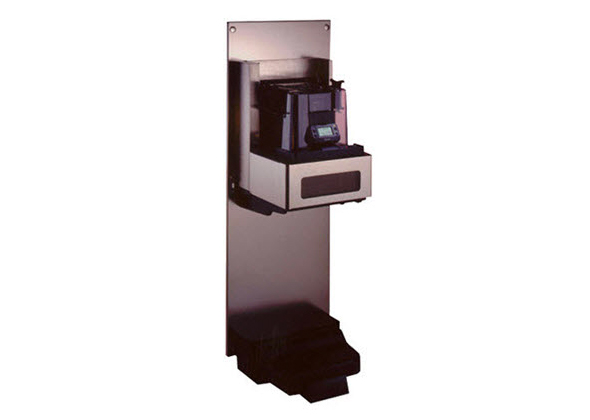

SMIF Load Port Transfer (LPT)

The SMIF-LPT (Load Port Transfer) is an ergonomically designed SMIF-I/O that easily integrates SMIF-Pod cassette loading and unloading into a wide variety of 200mm and 150mm wafer processing and metrology tools. The SMIF-LPT is designed for adaptive and equipment manufacturer applications for vacuum load-lock tools, which require an external lateral cassette transfer mechanism.

The SMIF-LPT is designed for adaptive and equipment manufacturer applications for vacuum load-lock tools, which require an external lateral cassette transfer mechanism.

The SMIF-LPT provides SMIF capability for a wide variety of wafer fab tools and leads the industry in reduced cycle time and reduced footprint.

Adaptive SMIF-LPT Solutions

Brooks adaptive SMIF-LPT solutions for open cassette 200mm process, metrology, and inspection tools offer cost-effective upgrades of non-SMIF tools to SMIF, thereby enabling the conversion of existing 200mm facilities for semiconductor manufacturing at technology nodes below 180nm. The three configurations address original equipment manufacturer (OEM) tools with difficult cassette landing stages:

- SMIF-LPT Tx offers a lateral cassette motion to address narrow cassette-to-cassette spacing

- SMIF-LPT Ty has an offset arm to accommodate narrow chamber openings

- These features can also be combined or upgraded on an existing SMIF-LPT

- A robust kinematic interface provides quick, accurate, and reliable mounting and removal (a hinge and latch option is available for equipment manufacturer integration)

- Wafer sensing and the reseating system prevent wafer breakage

- Wafer transfer is accomplished in a better than Class 1 mini-environment which ensures maximum protection from particulate contamination

- Fast load and unload cycle time leads the industry

- Integrated SMART-Tag Auto ID provides lot tracking and control

- Installed base of over 12,000 LPT/LPI units

Maximum Productivity & Profitability

- A robust kinematic interface provides quick, accurate, and reliable mounting and removal (a hinge and latch option is available for equipment manufacturer integration).

- Wafer sensing and the reseating system prevent wafer breakage.

- Wafer transfer is accomplished in a better than Class 1 mini-environment which ensures maximum protection from particulate contamination.

- Fast load and unload cycle time leads the industry.

- Integrated SMART-Tag Auto ID provides lot tracking and control.

- Installed base of over 12,000 LPT/LPI units.

SMIF-INX Indexers

SMIF-INX products are designed to supply wafer indexing for fixed Z-axis wafer handlers or cassette positioning to a fixed plan for Z-axis wafer handlers. With an installed base of over 15,000 units, the SMIF-INX has proven its versatility, functionality, and reliability.

Contamination control benefits of the SMIF system are well documented and reveal how the latest generation INX 2200 EP provides a substantial increase in die yield for fabs. Indexers meet SEMI E15 and E19 specifications and are CE certified.

With an installed base of over 15,000 units, the SMIF-INX has proven its versatility, functionality, and reliability.

Maximum Productivity & Profitability

- The internal PTFE-ULPA filtration system maintains a better than ISO Class 3 environment.

- SMIF-INX mounts directly into the process tool.

- DC Servo control with position feedback provides high-speed wafer indexing with minimal impact on tool cycle time ensuring positioning accuracy of ±0.005 inches (0.127mm).

- Patented laser-based sensing system provides precision wafer and slot location, wafer position mapping, cross-slotted wafer detection, and sensing of protruding wafers and automatic reseating.

- Quick disconnect assembly offers easy maintenance.

VersaPort 2200 SMIF-Compatible Load Port

The VersaPort™ 2200 is the industry’s most advanced 200mm standard mechanical interface (MIF) I/0 processing tool with its load port opener. While designed as a “bridge tool” for 200mm to 300mm transitions, the VersaPort 2200 also offers a solution for open cassette to SMIF I/O processing.

The Platform Mount VersaPort is ergonomically designed to easily integrate the SMIF contamination control technology for unloading and loading all 200mm SMIF-Pods.

The Platform Mount VersaPort is ergonomically designed to easily integrate the SMIF contamination control technology for unloading and loading all 200mm SMIF-Pods™. It performs unloading and loading of all 200mm SMIF-Pods to 300mm class tools.

In both load ports, a sophisticated feature set includes laser-based cassette slot/wafer mapping, cross-slotted detection, wafer protrusion sensing, and automatic wafer reseating.

Maximum Productivity & Profitability

- Open cassette I/O processing is available with a Manual Open Cassette Adapter (MOCA) option.

- VersaPort’s unique “Tilt-n-Go” kinetic interface enables quick, one-person installation and easy alignment. No realignment is needed after installation.

- SMIF contamination control technology delivers better-than-Class 1 performance per Federal Std 209-E.

- Advanced laser-based wafer detection employs a sophisticated feature set that includes laser-based cassette slot/wafer mapping, cross-slotted detection, wafer protrusion sensing, and automatic wafer reseating.

- IR-based reflective sensor provides excessive wafer protrusion sensing, detects wafers beyond re-seat capability, and engages emergency stop and brake.

- Integrated self-test diagnosis is included, and advanced diagnostic software is available for easy design-in and troubleshooting.

- A programmable horizontal cassette shuttle option allows wafer alignment to 300 mm standards and provides centerline positioning for adaptation to tool-side automation.

- SEMI and CE compliance supports low cost of ownership